The article describes the machines that make up the mill, in particular the rollermill.

We have already talked about cylindrical grinding (you can read about cylindrical grinding here). This process allows you to break the grain of wheat, sift the product and regrind it to obtain the flour. The machine used for the breakage and the regrind is called a rollermill.

The history of the rollermill

In ancient times, alternative grinding systems to stone grinding (you can read about stone grinding here), such as the rollermill, were developed.

The first news of an iron machine that could grind wheat goes back to the time of the Emperor Charles V of Spain. In 1500 he ordered the construction of grinding rollers equipped machines.

But only after 150 years machines with two grinding rollers, similar to the current rolling mills, were born. These machineries were able to crush grain.

The efficiency and the qualitative performance of the milling on several passages was realized. This gave a great boost to the milling evolution reaching its current characteristics around 1870.

Rollermill’s characteristics

It can be seen that these machines have maintained some characteristics unchanged for about 150 years:

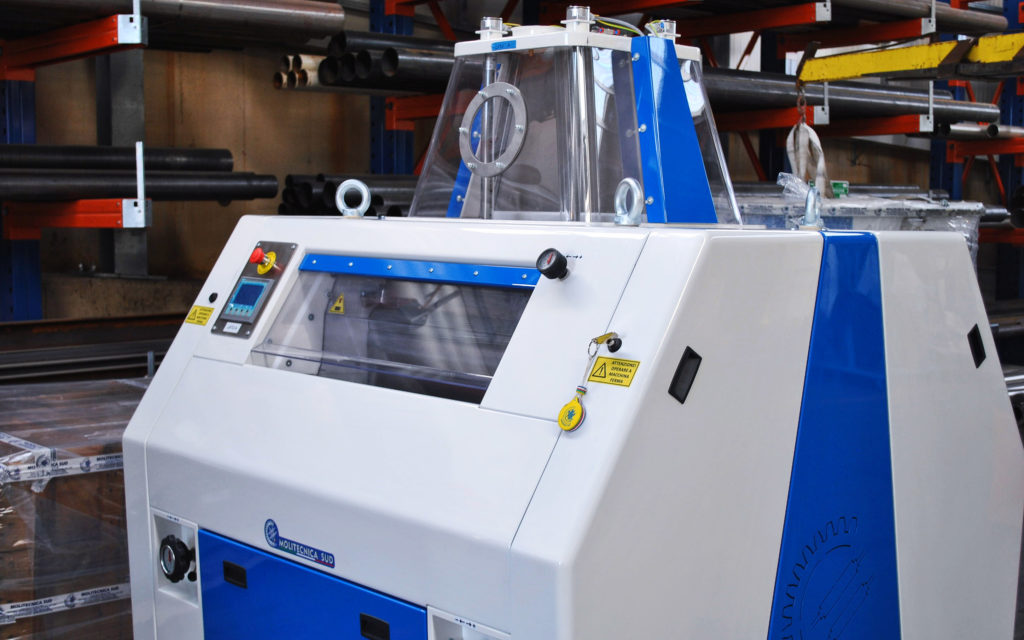

- The rolling mills are topped by a transparent bell through which the grinding product is loaded. It allows an immediate visual inspection of the product to be processed;

- The grinding product is sent to the pair of grinding rollers using feeding rollers. They ensure a regular dosing of the product;

- Each rollermill contains 2 pairs of rollers;

- The rollers are carved for the first grinding passages and smooth in the regrinding passages;

- The rollers that make up each pair are counter–rotating, and they move with differentiated speed. This is because for a correct grinding it is necessary, not only to crush, but also to break and stretch the grain of wheat;

- The rollers are enclosed in a metal frame that prevents the entry of unwanted elements;

- Distance between grinding rollers is adjusted by a lever system;

- The collection hopper collects the freshly ground product.

Modern rolling mills offer essential improvements compared to those of the past:

- Level sensors electronically adjust the speed of feeding rollers, depending on the amount of product in the bell;

- Increased hygiene level thanks to the elimination of wood and glass elements and geared transmissions in oil bath. Also due to the introduction of scrapers that keep the surface of the rollers clean;

The first Molitecnica Sud rollermill

Regarding Molitecnica Sud business reality, the first rollermill built in our establishment dates back to 2005. Today we are able to design and build not only high quality rollermills, entirely produced in Italy, but also complete grinding plants, suitable for every need. To find out more about our mill plants click here.

Comments (02)